How Stretch Wrapper Repair Service Functions: A Comprehensive Guide to Keeping Your Devices Functional

Stretch wrapper repair work is vital for maintaining the performance and reliability of packaging operations. Professionals frequently run into various problems that can impede efficiency. A methodical technique is essential for effective repairs. Recognizing common troubles and having the right tools can make a substantial distinction. Additionally, understanding when to do preventative upkeep can extend devices life. This overview checks out the details of stretch wrapper repair work and what it takes to maintain equipment in ideal problem.

Recognizing Typical Stretch Wrapper Issues

As the need for reliable product packaging services enhances, recognizing usual stretch wrapper issues comes to be important for maintaining functional efficiency. Stretch wrappers often encounter numerous widespread problems that can interfere with process. One usual concern is inconsistent film stress, which can cause inadequate lots security. This inconsistency might result from worn-out elements or misaligned settings. stretch wrapper repair. In addition, film tearing regularly happens, resulting in wasted materials and time. Wrong packing techniques or incorrect movie type can contribute to this problem.Another issue entails the maker's electric parts, which can malfunction and trigger operational delays. Routine upkeep is essential to guarantee that electronic systems, such as sensing units and electric motors, function properly. Ultimately, mechanical jams may happen, typically stemming from particles accumulation or worn equipments. Recognition of these problems enables operators to proactively resolve them, eventually enhancing the integrity and effectiveness of stretch covering procedures

Devices Needed for Stretch Wrapper Fixes

Effective repair services on stretch wrappers call for a specific set of tools tailored to resolve the usual concerns recognized earlier. Necessary devices include a socket and wrench set for loosening and tightening up bolts, which is important for accessing inner parts. A multimeter is essential for detecting electrical problems, permitting technicians to determine voltage and connection in the system. Furthermore, screwdrivers of various sizes are essential for eliminating panels and accessing components that may need substitute or adjustment.A measuring tape helps ensure precise placement during repairs, while pliers can assist in gripping and controling smaller parts. Lubricants and cleaning up agents are likewise necessary for keeping smooth operation and protecting against wear. Safety and security equipment such as handwear covers and safety glasses ought to be included to protect the technician throughout the repair service process. By equipping themselves with these tools, service technicians can successfully address a series of issues that might develop in stretch wrappers.

Step-by-Step Repair Refine

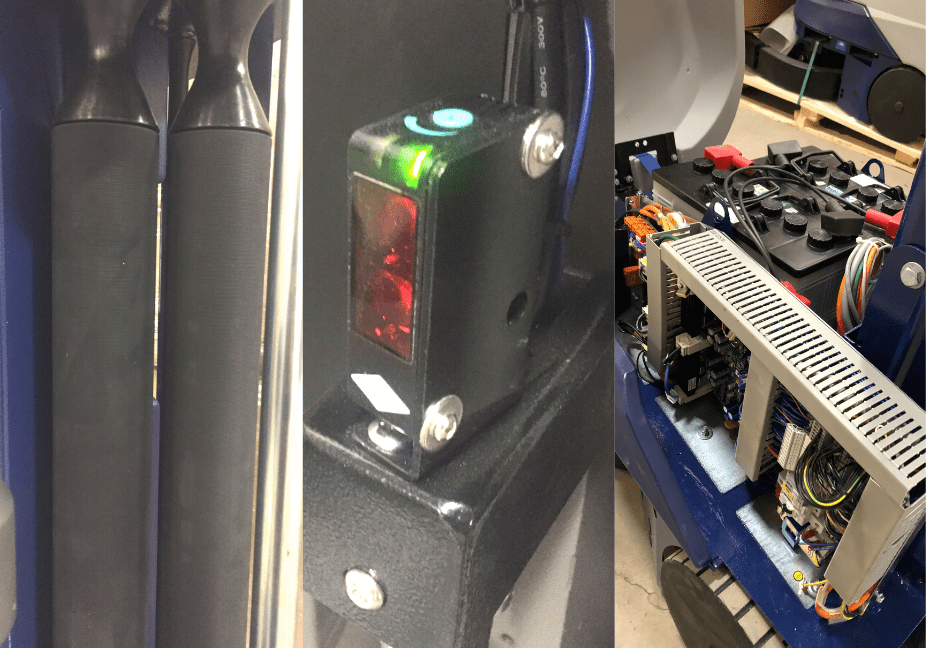

Begin the repair procedure by making sure the stretch wrapper is powered off and detached from the electric supply. Next off, check the machine for noticeable indications of damage or wear, focusing on key parts such as the film carriage, rollers, and sensing units. If any type of parts show up damaged, eliminate them very carefully making use of proper tools.Document the disassembly procedure to help in reassembly. Change damaged elements with OEM parts to keep efficiency criteria. After setting up repairs, reconstruct the machine, making certain all connections are protected and lined up properly.Once rebuilded, carry out an extensive inspection of all setups and configurations - stretch wrapper repair. Power the machine back on and run an examination cycle to confirm capability. Take note of any uncommon audios or breakdowns during procedure. If necessary, make more changes or seek advice from the supplier's handbook for fixing. Effectively record the repair service process for future referral

Preventative Maintenance Techniques

Applying preventative maintenance techniques is essential for extending the lifespan of a stretch wrapper and making certain peak performance. Routine inspections must be performed to determine any kind of indicators of wear or damages, concentrating on important parts such as sensors, electric motors, and belts. Cleansing the equipment routinely assists stop particles buildup, which can hinder operation. Lubricating relocating parts as per the supplier's guidelines decreases rubbing and extends the life of mechanical elements.Furthermore, preserving appropriate stress on the film and guaranteeing that the film rolls are stored appropriately minimizes pressure on the tools. Operators must be trained to recognize uncommon audios or motions during operation, as these can indicate possible issues before they rise. Developing a maintenance schedule that consists of changing used parts proactively can greatly lower the threat of unanticipated malfunctions. By sticking to these techniques, organizations can improve the dependability and effectiveness of their stretch wrappers.

Troubleshooting Tips for Quick Fixes

In resolving common stretch wrapper concerns, quick fixing methods play a vital duty in decreasing downtime. By comprehending the normal issues that occur, operators can apply effective maintenance ideal methods. This section will certainly check out functional services for swift troubleshooting.

Typical Stretch Wrapper Issues

Quick Repair Work Techniques

Upkeep Finest Practices

While normal upkeep is essential for perfect performance, executing ideal methods for fixing can additionally cause quick solutions. Recognizing and resolving typical problems immediately is crucial. Operators ought to acquaint themselves with the stretch wrapper's handbook, as it often consists of valuable fixing pointers. On a regular basis evaluating components like rollers, belts, and electric connections can avoid small troubles from rising. Maintaining a log of recurring issues assists identify patterns and remedies. Additionally, keeping a tidy work space lowers the risk of particles affecting equipment performance. When coming across an error, restarting the equipment can deal with many short-lived glitches. Using manufacturer sources and on the internet forums can likewise supply quick understandings from knowledgeable individuals, making sure that equipment remains functional with very little downtime.

When to Call an Expert Service Technician

When should one think about reaching out to a professional service technician for stretch wrapper repairs? Commonly, a specialist must be contacted when the tools experiences persistent problems that can not be dealt with with fundamental troubleshooting. If the stretch wrapper consistently stops working to run, shows mistake codes, or if elements such as the motor or control panel program indications of damages, professional aid is called for. Furthermore, if the equipment requires specialized devices or knowledge for repair work, getting a service technician ensures a correct resolution.Moreover, when the repair service tries cause a lot more complex issues or when downtime influences manufacturing timetables substantially, specialist treatment might be needed. Normal upkeep checks dig this can aid in recognizing potential concerns early, once a malfunction occurs that exceeds the driver's skill collection, it is sensible to call a specialist. This approach not only guarantees efficient repair services however also preserves functional efficiency and safety and security within the workplace.

Finest Practices for Tools Durability

To assure the long life of stretch covering tools, a normal maintenance schedule is important. Adhering to appropriate usage methods likewise plays an important duty in minimizing damage. Applying these finest methods can greatly expand the life expectancy of the machinery.

Regular Maintenance Arrange

A well-structured routine upkeep timetable is necessary for guaranteeing the durability of stretch covering devices. This timetable should consist of daily, weekly, and regular monthly tasks customized to the particular design and use problems. Daily evaluations need to concentrate on checking for indications of wear, making certain correct tension, and verifying that security features are functional. Weekly upkeep can include cleaning up the equipment and lubricating moving components to reduce friction. stretch wrapper repair. Regular monthly testimonials must encompass an extensive evaluation of electric elements and drive systems. Keeping thorough documents of maintenance tasks help in identifying patterns or recurring problems, helping with prompt interventions. Following this routine not just extends equipment life however likewise enhances effectiveness, decreasing downtime and repair expenses

Correct Use Methods

Regular maintenance is just one element of making the most of the life expectancy of stretch wrapping tools; proper use strategies likewise play a substantial role in boosting efficiency and toughness. Operators should be educated adequately to guarantee they understand the devices's performances and constraints. Consistently sticking to the supplier's guidelines for lots sizes and wrapping patterns is essential. Furthermore, keeping a clean operating atmosphere aids prevent particles accumulation, which can impede the machine's performance. It is vital to monitor the tension setups to avoid over-stretching or under-stretching the film, both of which can bring about ineffective covering. Verifying that the tools is run within its specified specifications will certainly lessen wear and tear, inevitably extending its operational life and lowering the need for fixings.

Often Asked Inquiries

How Frequently Should I Perform Routine Upkeep on My Stretch Wrapper?

Regular upkeep on a stretch wrapper need to ideally be performed every 3 to six months, relying on use. Regular checks can protect against breakdowns and assure peak efficiency, prolonging the maker's life-span and enhancing operational efficiency.

What Are the Signs Suggesting My Stretch Wrapper Needs Immediate Repair Work?

Indications that a stretch wrapper requires prompt repair consist of unusual sounds during operation, inconsistent covering stress, mistake messages on the control board, and noticeable damage to parts, showing potential failing that calls for prompt focus to avoid additional issues.

Can I Use Any Kind Of Lubricant for My Stretch Wrapper Components?

Making use of any kind of lube on stretch wrapper components may cause issues. It is crucial to utilize manufacturer-recommended lubricants to guarantee peak efficiency and prevent damages, as incompatibility can lead to malfunctions and boosted maintenance prices.

Exactly how Do I Choose the Right Stretch Cover for My Device?

Picking the ideal stretch wrap includes taking into consideration machine specifications, lots kind, and ecological factors. Examining density, stretchability, and width warranties suitable efficiency, protecting against damages while preserving product integrity during storage and transport. Proper selection is essential.

Is It Safe to Run a Malfunctioning Stretch Wrapper Briefly?

Running a malfunctioning stretch wrapper, even momentarily, poses considerable safety and security threats. It can lead to further equipment damage and enhance the probability of accidents, endangering both driver safety and security and overall efficiency in the work environment. As the demand for efficient product packaging solutions raises, understanding common stretch wrapper problems comes to be essential for preserving operational effectiveness. Reliable repair work on stretch wrappers call for a certain set of tools tailored to resolve the common problems identified earlier. In addressing usual stretch wrapper issues, quick repair methods play an essential role in reducing downtime. Dealing with these usual stretch wrapper issues immediately guarantees very little downtime, preserving performance and performance in product packaging operations. read here Utilizing any lube on stretch wrapper components may lead to issues.